A pulsed laser diode driver repetitively delivers sets of current pulses in specific time intervals. Choosing one for the intended application can be difficult. Only a handful of companies design and manufacture fast pulsing current sources. Pulsers designed by top companies ensure that the job done is a success.

Common Applications

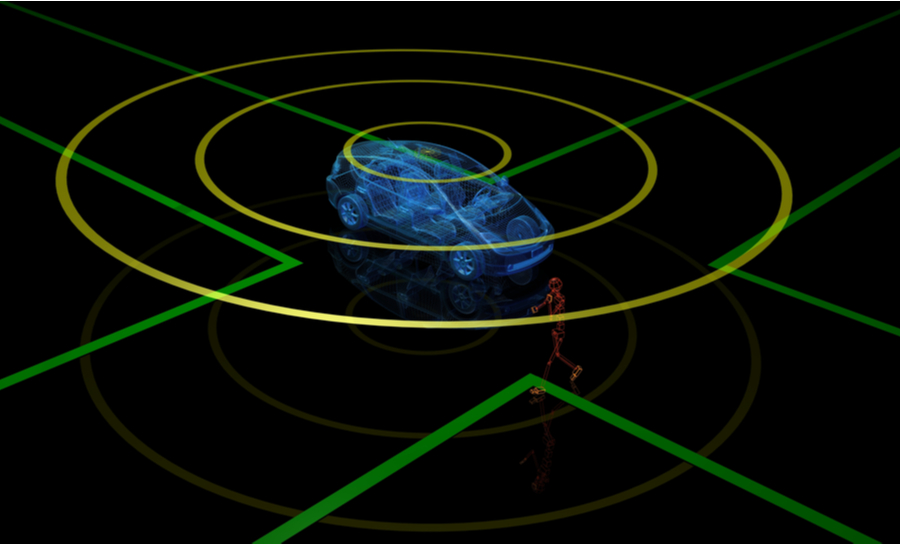

- LiDAR

- Range finding

- Medical applications such as tomography

- Fiber laser seeding

- Sensing

Essential Specifications to Consider When Selecting Pulsed Laser Diode Drivers

- Duty Cycle Limit

- Current Amplitude Range

- Compliance Voltage Range. Ranges between 3V to 10V

- Pulse Width Range. Usually measured in picoseconds, nanoseconds, and microseconds.

- Frequency Range

Common Problems When Pulsing a Laser Diode

Pulse degradation is the most common problem due to high repetition rates. Laser diodes have low impedance compared to current sources. To achieve a proper impedance matching, the load’s impedance and that of the transmission line must be matched.

The disadvantage of unmatched impedance levels is that inductance theory comes in. When the rate of current and the inductance changes, voltage increases. Inductors of the magnetic fields have energy that is released when the pulse ends. This causes the transmission path to creating a new current and a unique magnetic field, building a loop.

Pulse degradation is avoided by optimizing the pulsed launch pads’ impedance through the interface cable to the device being tested. Power output is lost if the impedance of the transmission line paths is different. Laser Diode pulses don’t absorb reflections because they are current sources. This is due to the mismatching of the load.

Critical Considerations of Impedance Matching

To minimize the common problems, the hardware between the laser diode and the pulsed should be necessary. It works best when the laser diode and the pulsed board are directly connected. Whenever a cable is being used, the current path should be short. This is to ensure a low resistance between the interconnects and the cable. The inductance should also remain low to maintain fast delivery of rising and fall times. To achieve this, the operator should avoid alligator clips, coaxial cables, and BNC jacks.

For a successful impedance matching, engineers use a copper stripline cable with low inductance and a wide surface area, solder wick, and a connector with a low inductance to form a current path. For the pulsed and the laser to achieve a matching impedance, multiple resistors are used parallel to minimize parasitic inductance. However, impedance matching depends on the laser diode package.

How the Pulse is Generated

External Pulses

Drivers have an input for the signal and specify that the pulse triggers on the rising edge. A voltage pulsed must be connected to it to activate the laser’s current pulses.

Internal Pulses

Some pulsars have internal pulse generators, while others have both internal and external. Internal pulses are generated from a pulse generation system called an onboard field-programmable gate array.

Those who require pulsed laser diodes should ensure to purchase from reputable companies. As such, they’ll get the best laser diodes for the application they are needed for. Engineers are knowledgeable and know how to choose the right laser diodes.