You might be aware of the functioning of hydraulics, where we practice automation by using the power of fluids. However, have you ever heard about the word pneumatics for valve actuators? Pneumatics is the relative of hydraulics where we use the air pressure in several industrial applications. In this technical article, we will discuss the science behind the pneumatics and how different tools and devices used in pneumatics, including the pneumatic control valve and actuator, control the overall working.

Pneumatics

Pneumatics is the science where we use gas or air to create pressure and rate to perform certain controlling actions. The industries use pneumatics on a routine basis for the automation control purpose.

In pneumatic valve actuators, we keep air or gas in the compressed state where is develops potential energy. When released such air or gas expands, and potential energy transforms into kinetic energy. This pressurized air travels through the actuator and offers the exact energy to move any object. However, the amount of energy or force required needs to be in check; that is where a pneumatic control valve comes handy.

Working Of a Pneumatic Control Valve Actuator

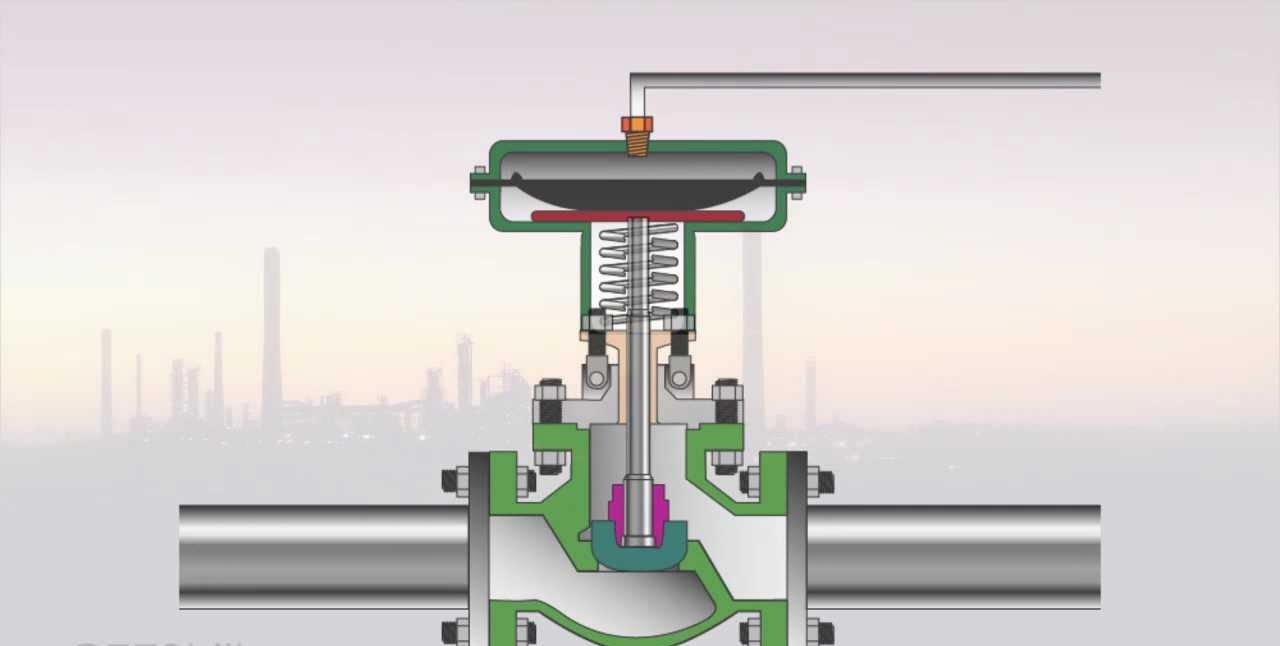

There are various forms and shapes of pneumatic valve machines; however, the machinery inside is almost the same. Let’s have a look at how the pneumatic control valve actuator work.

The machine keeps the pressurized air in a diaphragm or reservoir. While feeding the air into the diaphragm through the compressor, the air gets pushed against walls.

When there is adequate pressure in the area, the springs of the reservoir get compressed, which in return pushes the diaphragm downwards. Upon pushing the diaphragm down, the valve stem also gets pressed in the downwards direction causing the valve to be closed.

For opening the valve actuator, the air pressure gets released from the chamber, causing the springs of the diaphragm to uncoil, and the stem moves back upwards. Thus in this manner, we can control the movement of the machines by using the pressure control valve.

Function of Control Valve Actuator

Where in pneumatics, the compressors provide the compressed air, and the chambers hold the air, the control valves are the ones who actually control the movement of the compressed air and keep the entire system safe.

Here are some of the functions they perform in the pneumatic machinery:

- Pressure control:

The main function of the control actuator valve is to control the pressure. With the advancement in the industrial machinery, now we have the control valves, which allows partial or proportional opening to offer better control.

- Flow control:

Along with pressure control valves come the flow control valves that offer control over the flow of pressurized air from the actuator. The flow control valves adjust the flow in one direction to allow the flow of air from the opposite direction.

The pneumatic control valve actuators offer great control over the force required to move certain items or make various parts. Having the faulty valve in your machinery greatly impacts the speed accuracy and performance of the overall system.